- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Ready-To-Eat Foods

In today’s fast-paced society having access to ready-made food is an important convenience. With an increase in demand there is an increased need for production. One way to maximize productivity is to have food moving along a conveyor with employees adding ingredients as the product passes their station. Using a conveyor assembly line for ready-to-eat food is a more streamlined process because each employee is only in charge of one ingredient instead of having to make the entire product.

Benefits of Dorner’s Ready-to-Eat Conveyors:

Food safety is another important factor for ready-to-eat food conveyors, such as making sure that there are no of areas where water or food can collect.

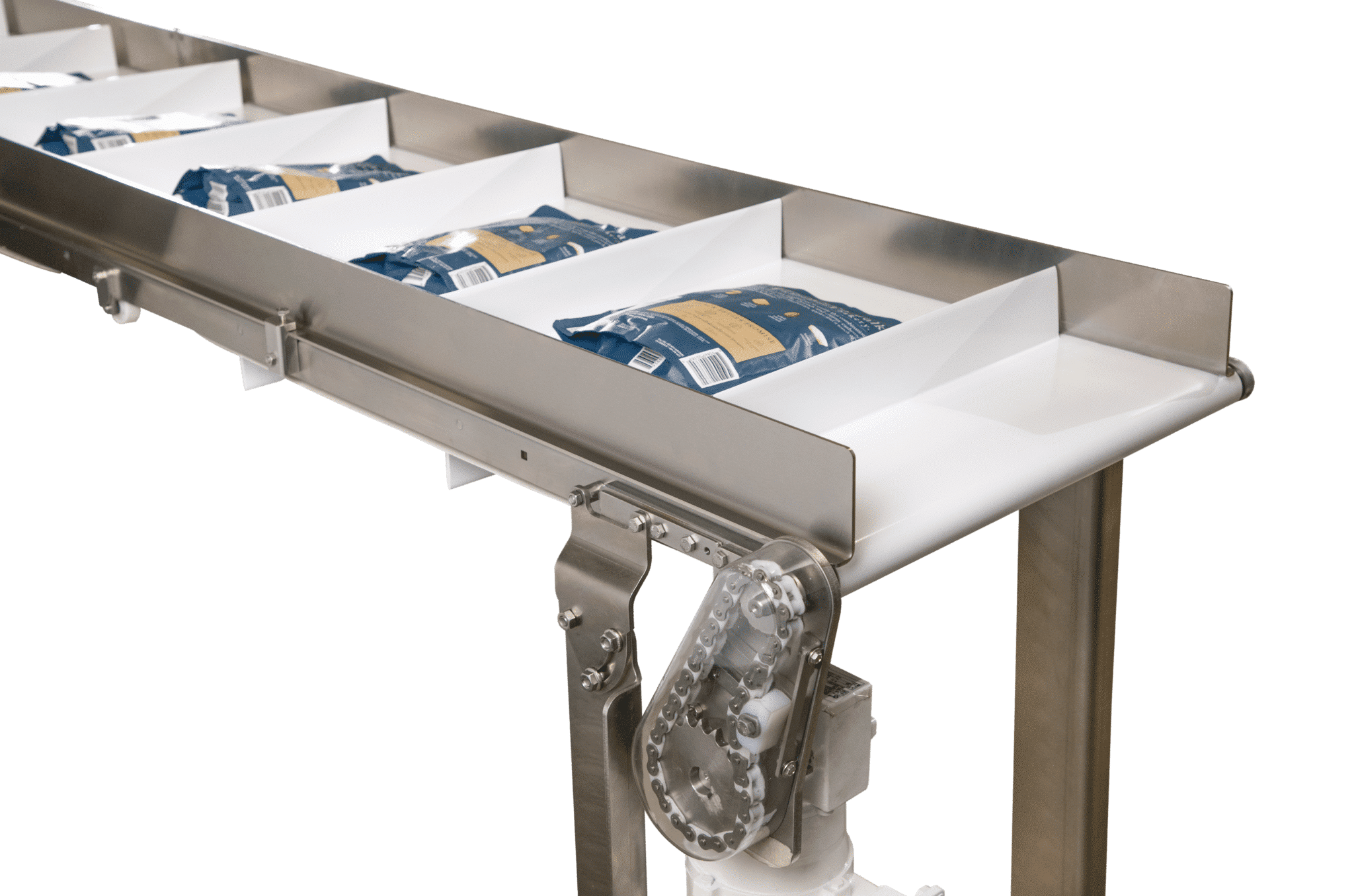

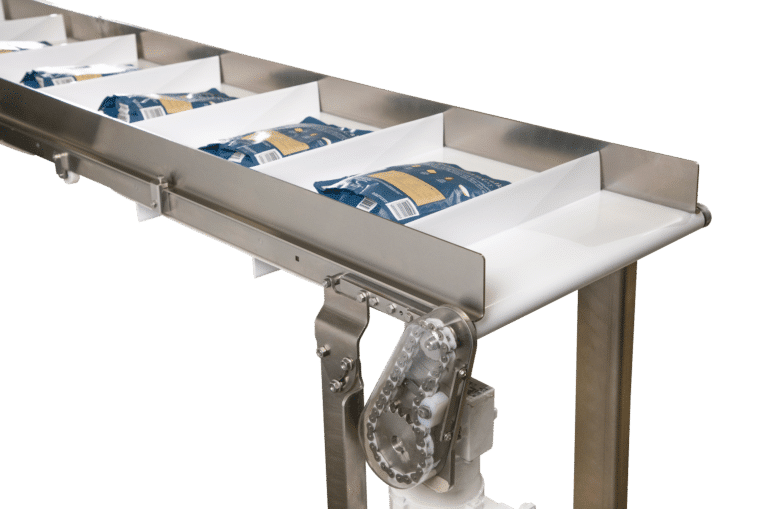

AquaPruf® Series Conveyors

- Tip-up, tool-less pulleys and belt lifters for easy access for cleaning

- Rounded cross members to eliminate horizontal edges

- Solid UHMW wear strips for quick drainage and easy cleaning

- V-guided belt tracking

AquaGard Series Conveyors

The AquaGard line of conveyors is designed for a wide variety of packaged food applications in sanitary environments that require conveyor wipe-downs. Features include:

- Solid UHMW wear strips located in welded cross members for durable belt support

- Frame constructed of TIG welded 304 stainless steel

- Open design with minimal horizontal surfaces

- Low-profile frame and flexible belt options

Engineered Solutions

At Dorner we recognize that our standard conveyor solutions aren’t always right for everyone. Our Engineered Solutions Group specializes in designing and implementing custom solutions for our customers. Our team of engineers will work with you to make sure that you get a quality conveyor system that fits your specific needs. In the food industry especially where each application differs greatly we are able to custom design a solution to fit your unique needs. Check out this blog post about a custom solution we created for a ready-made sandwich producer that made sure their line was running smoothly and efficiently.

Conveyors Ready-To-Eat Foods

AquaPruf Conveyors

- Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

- Spiral cam belt tensioning with patent pending thread-less design

- Patented sprocket alignment key

- Gearless, oil-free iDrive2 sanitary motorized roller

AquaPruf Ultimate Conveyors

AquaGard LP Conveyors

- Quick five-minute belt change for increased uptime

- Compact and enclosed tensioning system providing smooth and snag-free cleaning

- 304 stainless steel frame, head and tail plates

- V-Groove frame with guided belt ensures accurate tracking

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Streamlined design fits where other conveyors do not

- Low-profile, operator safe design with no pinch points

- Small 1.25 in (32 mm) diameter rollers for transfer of small products

- A variety of FDA approved belting to meet application needs

Dorner — Asia

Dorner (M) SDN. BHD.

128 Jalan Permatang Damar Laut, Bayan Lepas 11960

Penang, Malaysia

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy